Read the article below, originally posted by TruckNews.com, to learn more about Hyundai Translead’s major technological breakthroughs in trailer design, including their new advanced fiber core composite panel.

Hyundai Translead has enhanced its 2021 dry and refrigerated van trailers in the name of shedding weight and improving durability – and introduced a lightweight polymer fiber core composite panel.

Changes that come to the enhanced lightweight composite dry van trailer save 330 lb. per trailer. Features include a new rear header, standard side panel and side rail designs.

The upper coupler has been fully hot-dipped galvanized to fight corrosion. And maintenance has been eased through harness routing in the rear door header and the side composite panels, the company says. Roll forming is used to reduce components in the rear header and impact guard.

The upper coupler has been fully hot-dipped galvanized to fight corrosion. And maintenance has been eased through harness routing in the rear door header and the side composite panels, the company says. Roll forming is used to reduce components in the rear header and impact guard.

The updated lightweight refrigerated trailer, meanwhile, sheds 680 lb. per trailer, and enhanced designs have increased the strength of flat and duct floors with floor ratings of 20,000 lb. Weight savings here come in part through the use of reinforced polypropylene in the floor — and that also increases “flexural strength” by 30%, Hyundai Translead says.

Design changes on the front structure, upper coupler, and front interior connection help to block moisture.

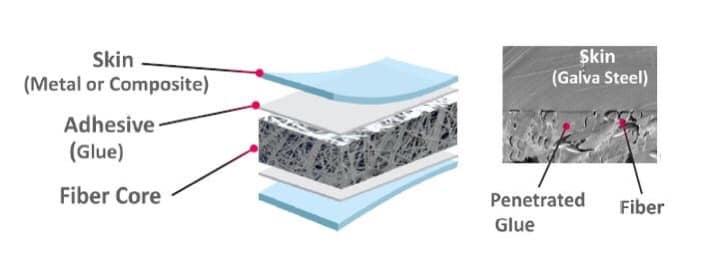

Rounding out the updates is a new fiber core composite panel that was engineered over the past three years during a collaboration with LG Hausys.

Made of a galvanized steel skin and fiber core, it reduces weight and reduces thermal losses, the company adds.

The polymer fiber core allows for a thinner outer composite layer. Available on dry van trailersA dry van trailer is a type of enclosed trailer commonly used in the transportation industry to haul and protect a wide range of goods. Unlike open trailers or flatbed trailers, which have an open platform, a dry van trailer is fully enclosed, providing a secure and weatherproof environment for cargo. It is one of the most prevalent types of trailers used for over-the-road freight transportation. More, it can save 155 lb. in addition to the 330 lb. already saved with the standard conventional composite panel.

Fibers in the panel’s core are mechanically bonded to improve strength, while the adhesive is anchored to the open cell for a longer-lasting bond, the company says. The enhanced peel strength controls water intrusion that would otherwise lead to delamination and cracks.

The fiber core reduces thermal transmittance up to 25%, which would otherwise let condensation form inside the trailer.